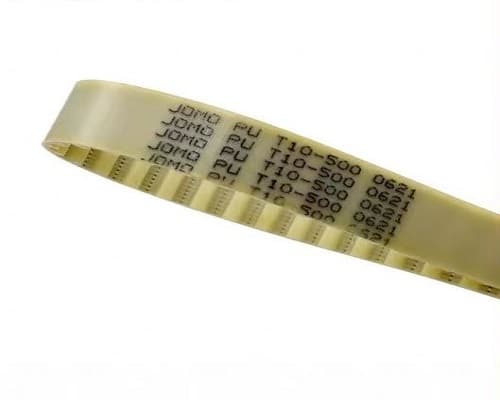

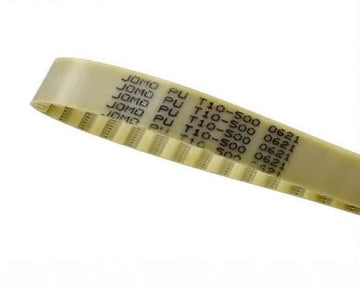

Polyurethane timing belt

Polyurethane timing belt

During the production process of polyurethane timing belt, the steel wire rope is wound on the mold, which can produce the size structure suitable for different applications to meet customer requirements. In some high power or high positioning accuracy applications, molded polyurethane timing belts need to be stronger than spliced belts. It can provide high power transmission and high positioning accuracy capabilities, and can also drive more loads.

Features/Advantages

- Mold making, castable (CPU) polyurethane structure

- Stable operation, low noise, no contact marks

- The transmission capacity is equivalent to that of a closed loop belt

- high tooth shear

- excellent wear resistance

- Good chemical resistance

Representation

The naming of polyurethane synchronous belts consists of width, pitch, and pitch line length, such as 10 T5/455, 10 represents 10mm width, T5 represents 5mm pitch, and 455 represents 455mm pitch line length. The belt pitch refers to the distance between the centers of two adjacent teeth measured on the pitch line, in millimeters. Belt pitch line length is the total circumference measured along the belt pitch line. .

Polyurethane timing belt model

| MXL/XL/L/H |

| T2/T2.5/T5/T10/T20 |

| AT3/AT5/AT10/AT20 |

| ATP10/ATP15 |

| F/AF/BF/CF/DF |

| K1/K1.5 |

| T2.5-DL / T5-DL / T10-DL / T20-DL |

Hardness 88 Shore

Steel wire rope (customized Kraft rope)

Width 3-250mm

Length 120-4780mm